“KINEMATIK SNC”‚ is an automatic positioning system (SNC). It is a simple and, at the same time, an extremely useful solution because it provides the possibility of conducting a large number of activities by programmed movements at specific programmed speeds.

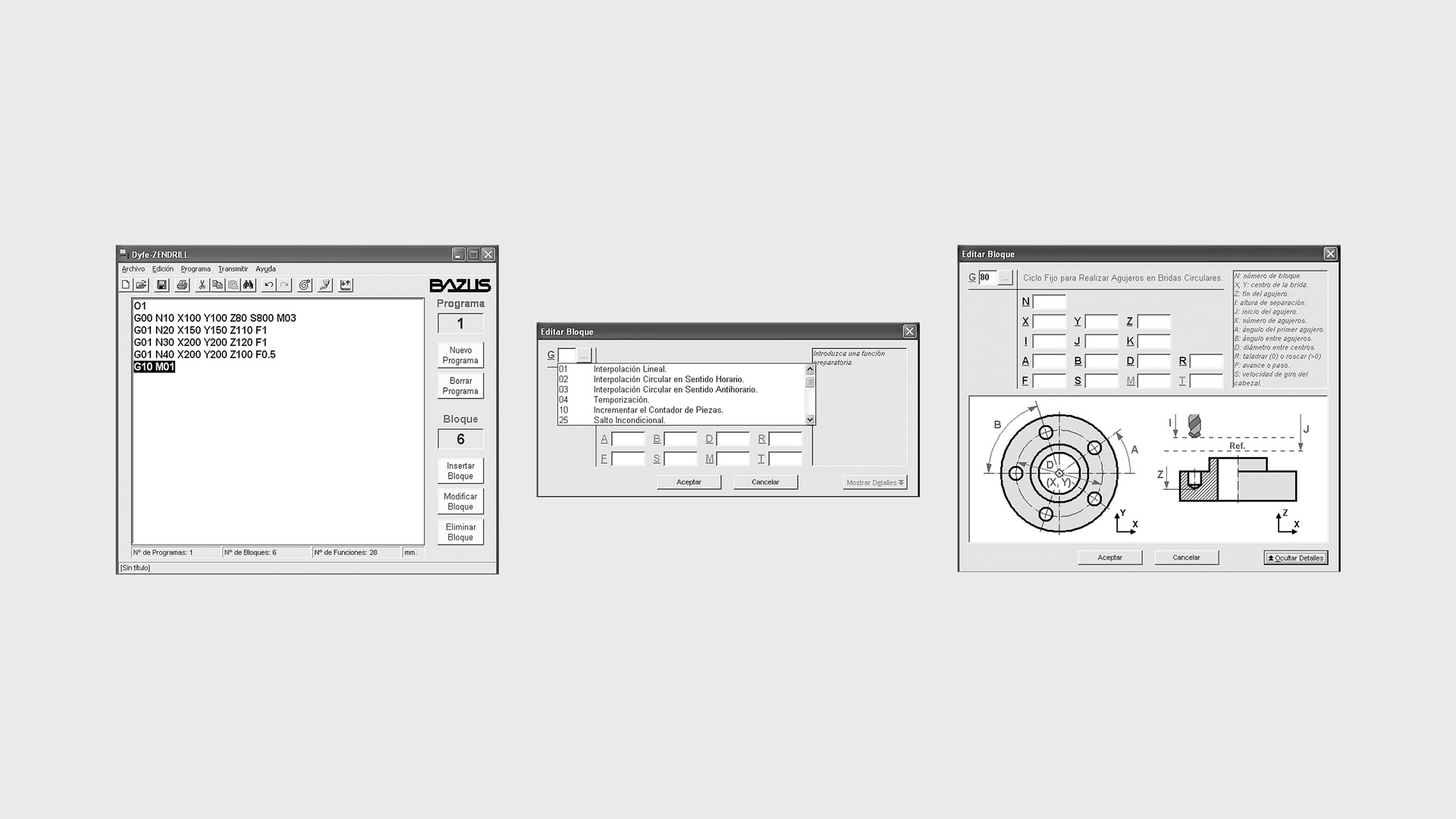

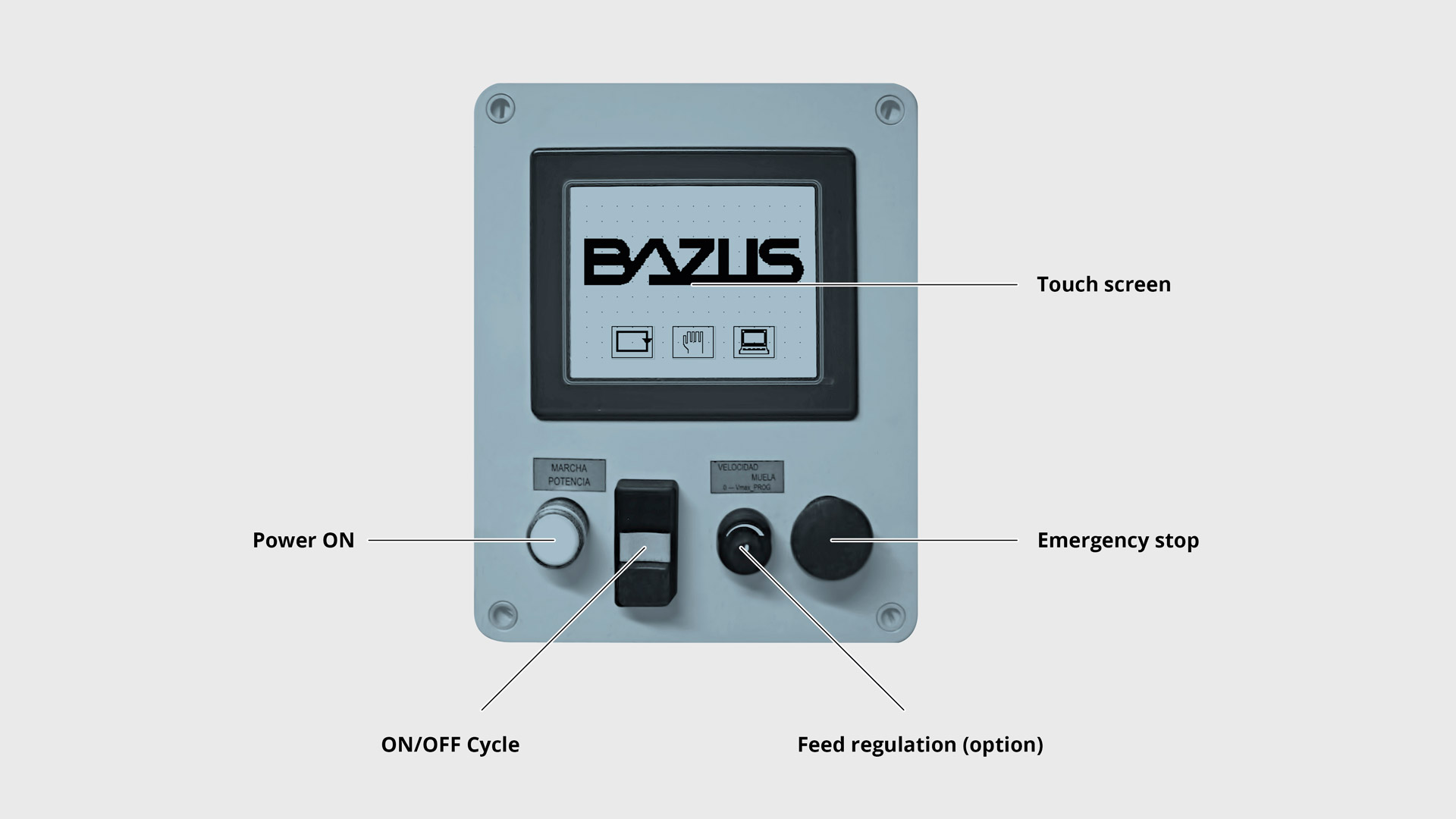

KINEMATIK SNC is controlled by means of the “Quick Panel”, where user find all information to operate with the system in any of its Working Mode (Automatic, Manual and PC Communication). “Quick Panel” is equipped with “Touch screen” to select the Work Mode, buttons Power ON/OFF, Cycle ON /OFF and Emergency Stop.

Technical details

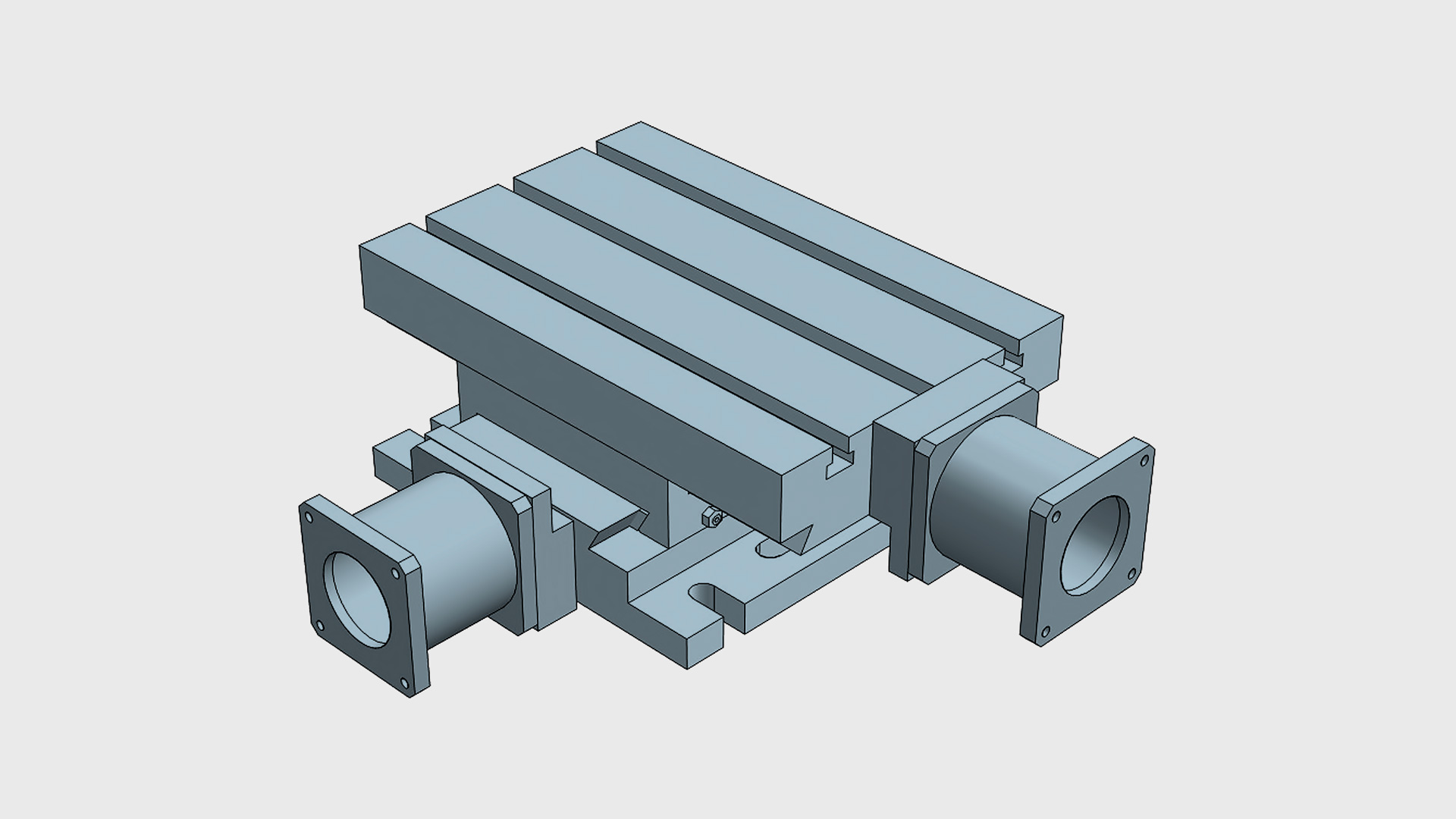

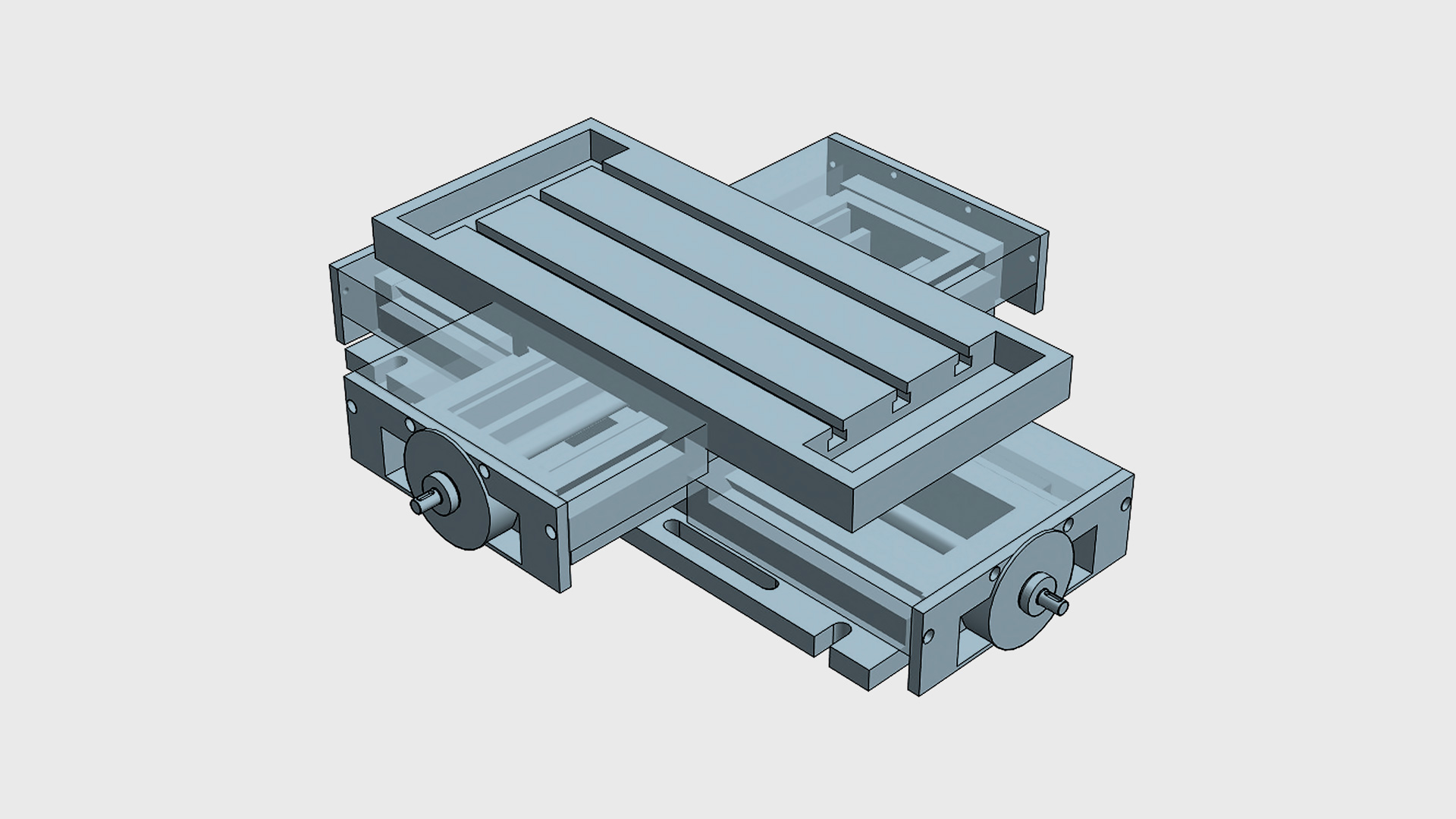

The BAZUS Slide units controlled by means of the KINEMATIK SNC are equipped with following equipment in the standard version:

• Preloaded ball screws with double nut (high accuracy)

• Displacement by means of linear guides (big load capacity) or dovetailed guides (ant vibration)

• Special bearings high accuracy in all units

• SNC “Quick Panel” with high resolution touch screen

• Brushless motors

• All elements ready to plug and work (easy start up)

• Construction in stabilized high quality cast iron GG25

• Feed range 12-7000 mm/min

• Screen resolution: 0.01 mm

• Positioning accuracy: 0.01 mm

Under request, the BAZUS Slide Units can be also equipped with any other standard CNC (Fagor, Fanuc, Heidenhan…)

Quick panel

The BAZUS units equipped with the Kinematik CNC are supplied ready to connect and work:

• Kinematik table with motors and HOME/ZERO reference mounted all items ready and verified, ready to connect and work.

• Electronic board with all the electrical and electronic elements necessary for calculations and positioning.

• “Quick Panel” control with touch screen for selection of work mode, emergency stop, cycle start / stop. Connected with “Electronic board” with 5m cable, allowing the user to place the Quick Panel in the most suitable position.

Working mode

KINEMATIK tables are able to work in 3 different “Working Modes”. Trough the Touch Screen user can select appropriated Mode.

Mode Selection

• Automatic

• Manual

• Communication

1.- Automatic Mode

ISO friendly environment Programmation trough Ginstructions (G00, G01, G90…) and M functions (synchronization with external devices).

2.- Manual Mode

Actual position read out / HOME reference & LIMIT switches / Feed and displacements with visual icons.

3.- Communication Mode

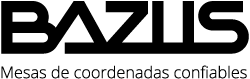

Only for users with DYFE (PC Windows) software, which allows user to programme the KINEMATIK system with a PC and connect the system trough RS232 output.

| G |

Data |

Description |

| G00 |

N XYZ M S |

CP-0 |

| G01 |

N XYZ F M S |

Lineal interpolation max. Feed |

| G02 |

N XYZ F U M S |

Circular interpolation right |

| G03 |

N XYZ F U M S |

Circular interpolation left |

| G04 |

N K |

Chronometer (in seconds) |

| G10 |

N M |

Increase the piece counter |

| G25 |

N K R |

Repetition / Cycle loop |

| G55 |

N M T D |

Tool length |

| G90 |

N M |

Change to Absolute programmation mode |

| G91 |

N M |

Change to Incremental programmation mode |

| G92 |

N XYZ |

Coordinates selection as ZERO |

| G93 |

N M |

Cancel G92 selection |

| G94 |

N M S |

Change to mm/rev (tapping) |

| G95 |

N M S |

Change to m/min |

Accesories

KINEMATIK tables can be equipped with the any special accessories required by the application: Output signal (synchronization with external device; available till 20 outputs), increase of speed, (for applications in which high speed is required), or any other special equipment (feed regulation, electronic hand wheel, tapping function…)

Software DYFE for PC Communication: The software “DYFE” developed by BAZUS is a powerful tool for programming the KINEMATIK systems in a friendly PC WINDOWS environment. “DYFE” is extremely easy-use software (usability) that allows user to programme movements and speeds by ISO code instructions. Moreover “DYFE” offers Help Windows for programmation where user can find all information and instructions to programme in an intuitive way.

Drawings and documents

Download PDF