Reliable coordinate tables

Why customers trust BAZUS

Tailored solutions for each customer

Customers and applications are never the same. Even not similar. All are different. Every client is unique, and we know better than anyone. We offer the solution that best suits to each of them, making everything work perfectly.

Efficacy and design in your hands

We offer to our customers the simplest & efficient solution for any market requirement. Our customers demand: quality, reliability and innovation.

Quality and reliability

Quality is the basis of our design and our product planning. More than 25 years of experience. Solvency. European manufacturers. Experts in linear movement.

Durability

Manual and automatic tables. Thanks to its robust technology, high quality iron and our practical Solutions. Crosstables to do all you can imagine.

X Coordinate tables

Using the traditional robust BAZUS design, the range of manual coordinate tables are operated by trapezoidal spindles and dovetailed guides. Made from high quality stabilized cast iron, this product range comprises single axis (X) slide units.

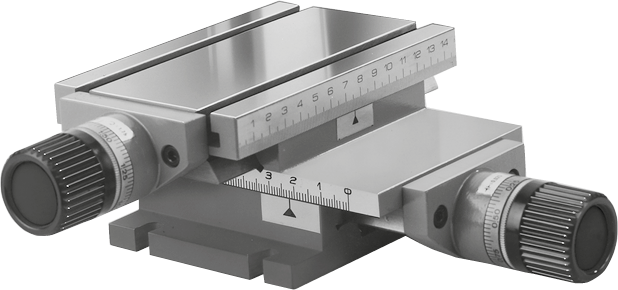

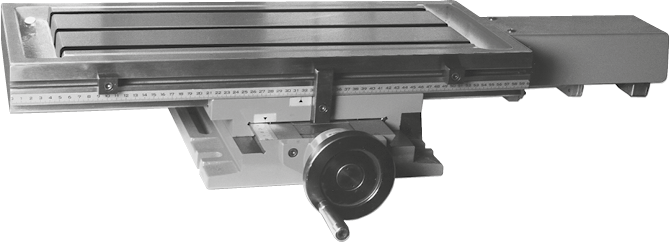

XY Coordinate tables

Fixed double axis cross tables, designed to be used on drilling and milling machines, special transfer assemblies and in any mechanical application in which X-Y movement has to be controlled.

MINI Coordinate tables

MINI tables. Tables for applications in small mechanical operations and testing and metrology laboratories. Their compact design and highly sensitive movement make them extremely versatile in use

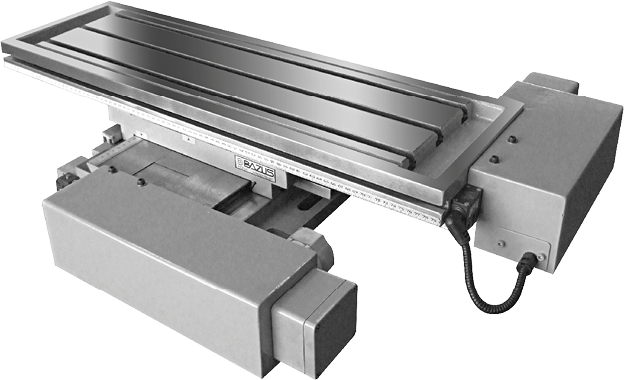

CNC Coordinate tables

The BAZUS automatic series has been developed for automated industrial process applications. The system is designed mechanically and electrically according to the degree of automation required and the precision and repeatability needed.